· When a maximum quantity of steel received at construction site, first check the Manufacturer test certificate for its actual properties which is sent by Manufacturer Company.

· At every lot of steel manufacturing, manufacturer should send a test certificate of same lot for test done at their laboratory.

· Check for grade of steel mention in certificate and is as per required order or not.

· Many of steel bars may have rusting on it, do check closely to know either it is acceptable or not.

· Steel bar received should be free from any contamination like, mud, dust, oil and any other foreign material etc.

· If straight bar is better than bend bar, it is good to use straight bar because at bent section bar doesn’t give yield stress as per design so we have to cut and remove the bend bar.

There are two way to check the Reinforcement Steel Bars that is given below :-

· On Laboratory

· On Field Test: -It is not quite accurate but at site for quick decision for construction we generally follow these steps to test the reinforcement steel bar.

a. Weight Per Running Meter

Collect and cut samples of 1 m Length from every diameter of steel, minimum 4 numbers of bars from different bundles and each diameter of steel. Weight the bar on weight scale and record it in register for different dia weight can varies. Calculate the actual average weight per meter of bar by =(d*d)/162 . Compare the result of it with theoretical weight given in formula .Check the variation in weight is within limit or not as per specification.

b. Bent Test

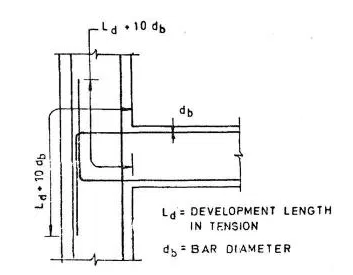

Cut sample (3-4) m of its length and bent at 180 degree repeat the procedure as shown in figure

After doing the given process check bar the surface of bar opposite to bend side (which got tension, elongated due to bending) for cracks and rupture visible to a person with normal or corrected vision. If there is no sign of rupture and cracks, rebar meets the requirement of bend test. Generally for good bar rupture and crack do not occur at 3 attempts.

For better knowledge about this check in IS 1599 using mandrels of size specified in IS 1786 and procedure in IS 1599

c. Re-bent Test

· First bend the bar to including angle of 135 degree.

Keep it in boiling water at 100 degree for 30 minutes.

Then cool it down for some time.

After cooling bent it back to including angle of 157.5 degree

Keep it in boiling water at 100 degree for 30 minutes.

Then cool it down for some time.

After cooling bent it back to including angle of 157.5 degree

· The rebar should not show any rupture or cracks to a person with normal or corrected vision.

· After getting satisfactory results, you can approve the steel for further usage in actual construction.

0 Comments